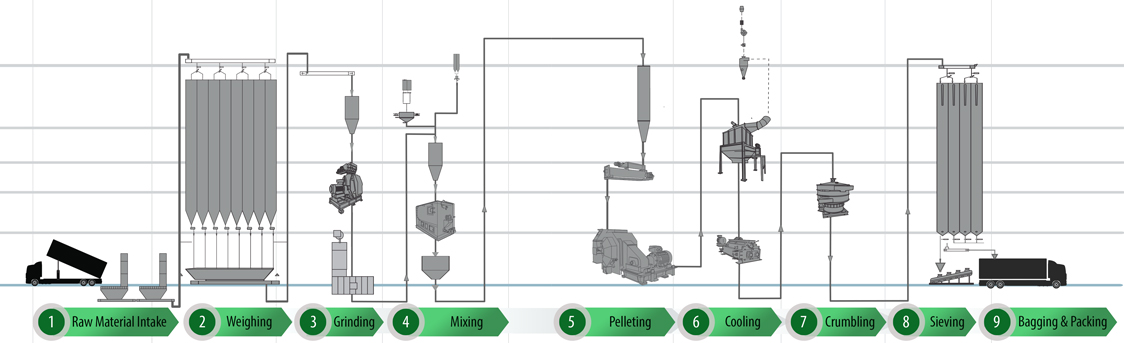

Feed Milling Process

1 Raw Material Intake

Raw feed ingredients are stored and fed milling process.

2 Weighing

Feed ingredients like maize soya etc. are weighed and introduced into the process.

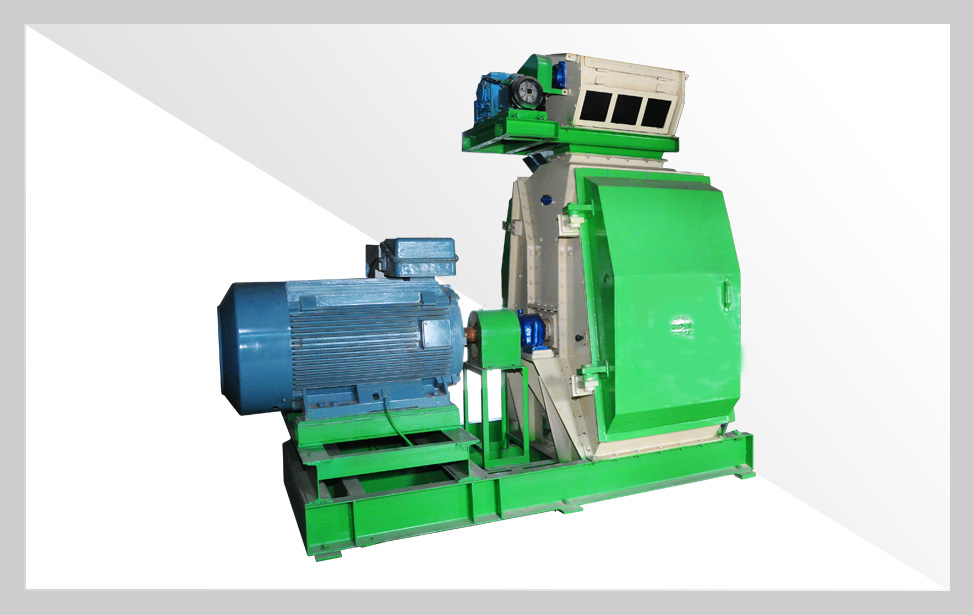

3 Grinding

Grinding of material is done to reduce the particle size for further processing of feed.

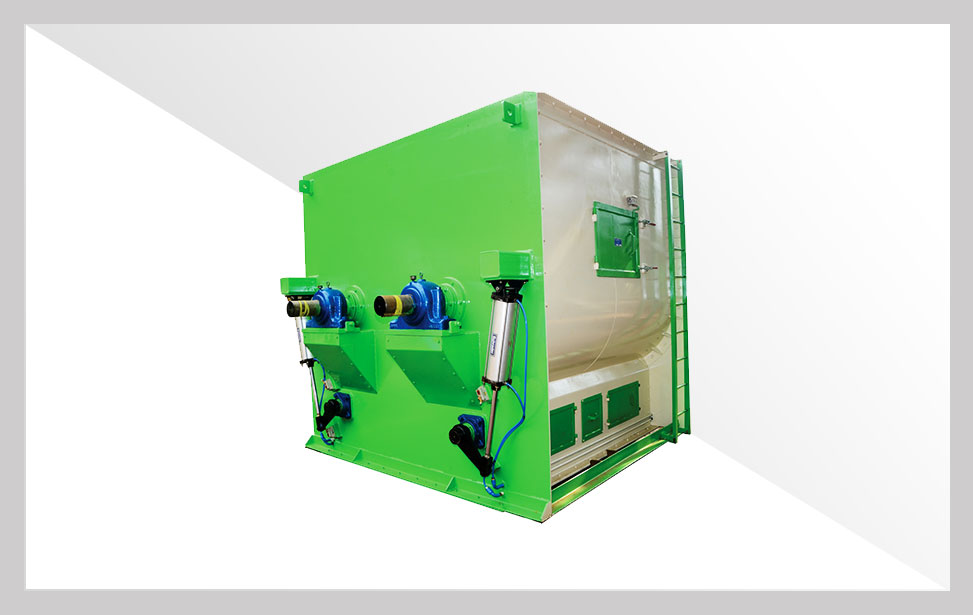

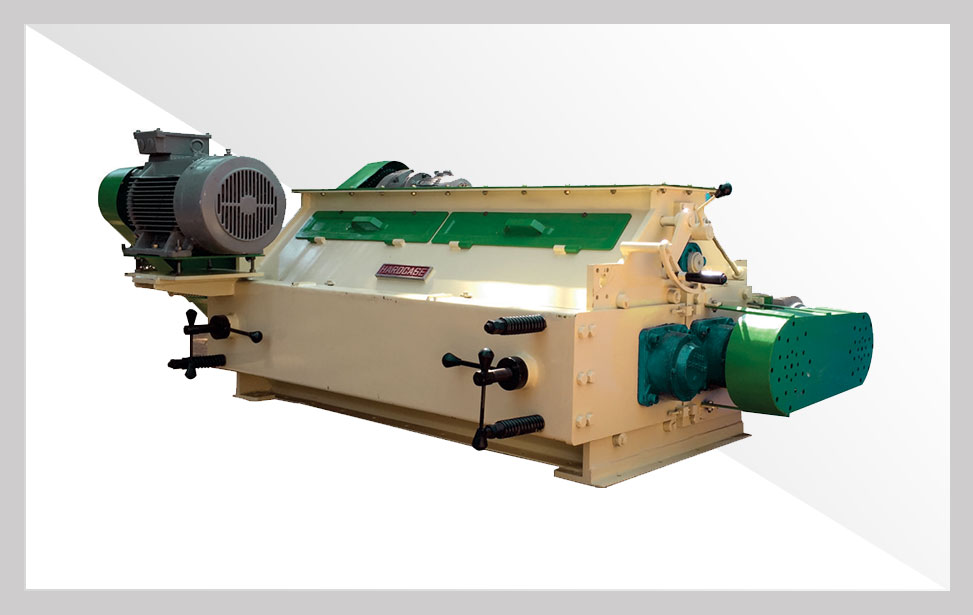

4 Mixing

All macro, micro and liquid ingredients in the feed composition are mixed batch wise.

5 Pelleting

Mash feed produced after mixing is converted to pellets by mechanical combination with heat & moisture.

6 Cooling

Hot pellets after pelleting are cooled to remove excess heat & moisture.

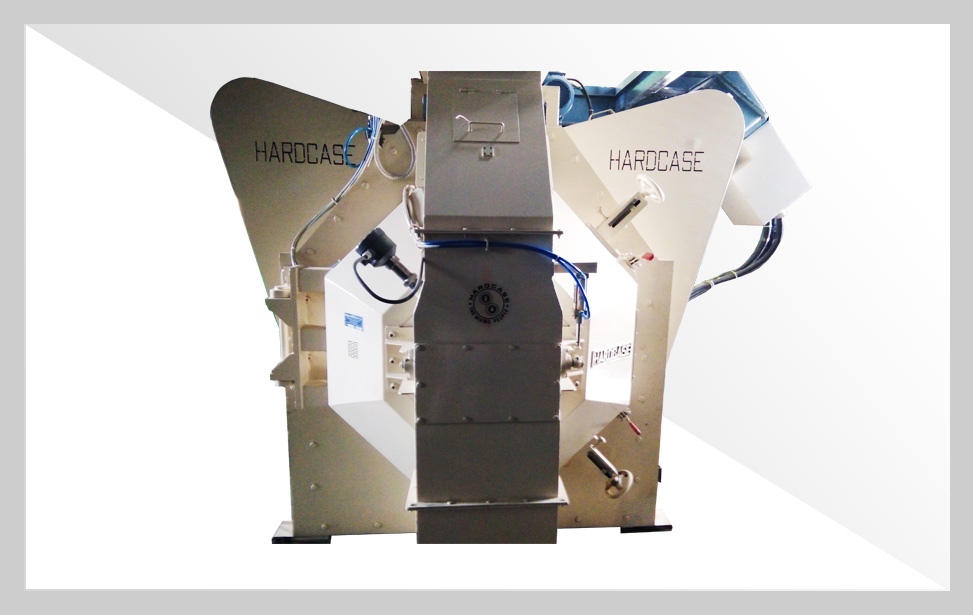

7 Crumbling

Pellets are broken down into smaller pieces to make them palatable for day old chicks.

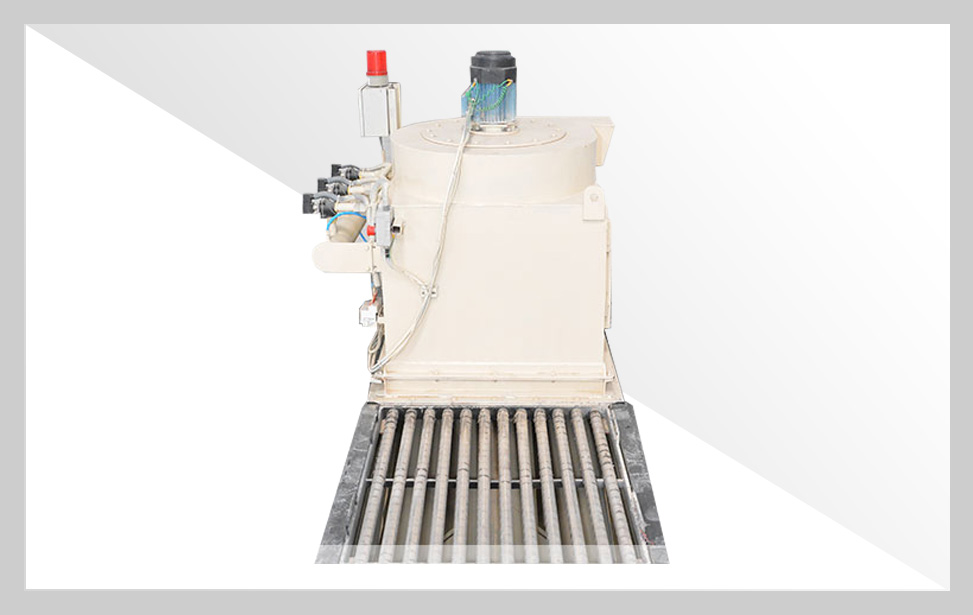

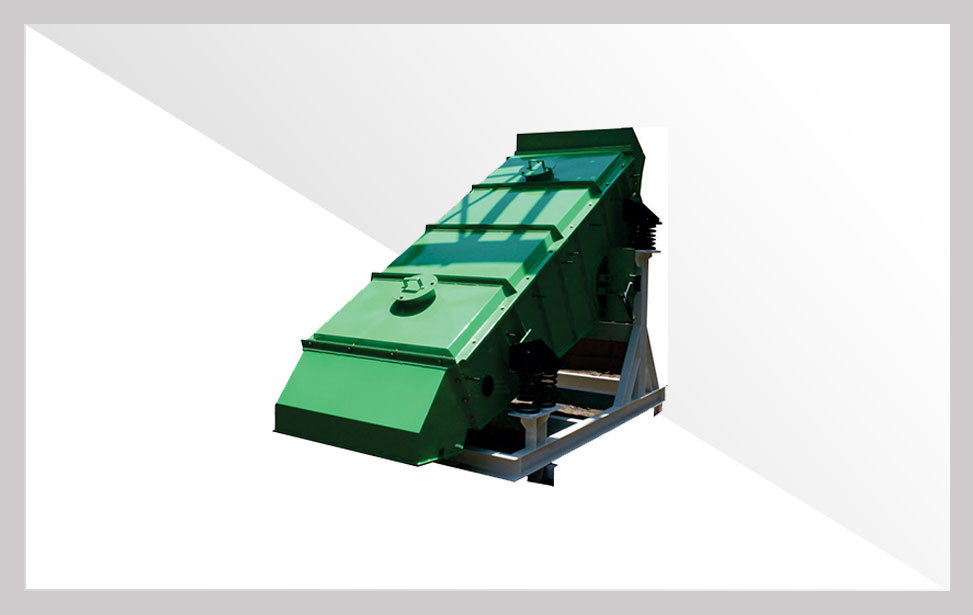

8 Sieving

Pellets or crumbs are screened to separate fines and over size particle from the desired product.

9 Bagging & Packing

The end product is weighed and packaged as required for transporting to the end user.

Our Clients